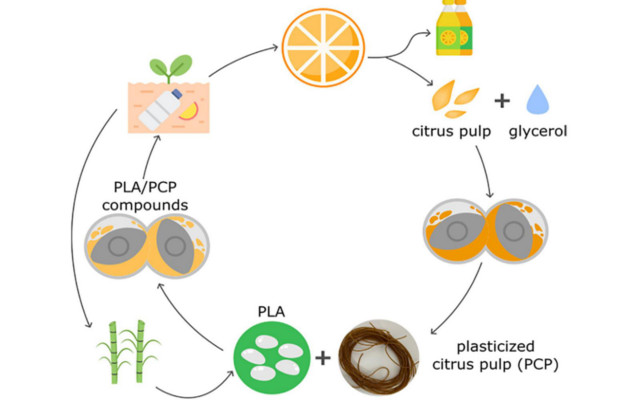

The escalating crisis of plastic pollution demands innovative solutions that address both environmental sustainability and resource circularity. A recent study published in Future Foods presents a promising pathway for valorising agri-food waste by converting orange processing by-products into biodegradable plastic compounds (Possari et al., 2025). With global orange production reaching 70 million tonnes annually, approximately 45–60% of processed fruit becomes residual biomass, typically destined for landfills, incineration, or low-value applications (Panwar et al., 2021). This research demonstrates how citrus pulp (CP), a particularly underutilised fraction from juice production, can be transformed into functional bioplastic materials when combined with poly(lactic acid) (PLA), a biodegradable polymer derived from renewable resources.

The researchers employed a systematic approach to maximise citrus pulp utilisation whilst optimising material properties. Fresh citrus pulp obtained from the finishing step of orange juice production underwent washing with ethanol to remove soluble sugars and was subsequently dried at 60°C (Possari et al., 2025). The CP was then plasticised with glycerol at varying concentrations (40%, 50%, and 60% by weight) through extrusion-assisted processing at 140°C, creating plasticised citrus pulp (PCP) compounds. These PCP materials were subsequently melt-blended with commercial PLA using twin-screw extrusion at temperatures ranging from 150–160°C.

The investigation utilised a 2² factorial design with a central point to evaluate the influence of two critical variables: PCP content (30%, 50%, and 70% w/w) and glycerol content (40%, 50%, and 60%) in the PCP phase. Injection-moulded specimens were subjected to comprehensive characterisation, including mechanical testing (tensile properties), differential scanning calorimetry (DSC) for thermal behaviour, and soil burial degradation studies extending to 90 days. Molecular weight variations were assessed through size exclusion chromatography (SEC) to track polymer chain scission during biodegradation processes (Possari et al., 2025).

Results and discussion

The mechanical characterisation revealed that PCP incorporation produced a progressive toughening effect on PLA, with strain at break values increasing from 4.3% for neat PLA to 7–9% for most PLA/PCP compounds. However, this enhanced flexibility came at the expense of stiffness and strength, which decreased significantly as PCP content increased. The tensile strength declined from 54 MPa for pure PLA to values ranging from approximately 10 to 25 MPa depending on formulation, whilst Young’s modulus decreased from 3.3 GPa to 0.5–1.5 GPa (Possari et al., 2025). These mechanical property changes were primarily influenced by PCP content rather than glycerol concentration, suggesting that the dispersed phase morphology plays a more critical role than plasticiser levels within the tested range.

Thermal analysis provided insights into the structural changes induced by PCP incorporation. The glass transition temperature (Tg) of PLA decreased from 60°C to 53–55°C upon blending with PCP, indicating increased molecular mobility attributed to glycerol migration and interaction with the PLA matrix. Calorimetric measurements revealed that PCP enhanced PLA’s crystallisation potential, with cold crystallisation and melting enthalpies increasing compared to neat PLA, although overall crystallinity remained low (0.1–2.5%) across all formulations (Possari et al., 2025). The emergence of a double melting peak in PLA/PCP compounds, attributed to the melting-recrystallisation phenomenon of PLA’s polymorphic phases, became more distinctive due to enhanced chain mobility (Song et al., 2013).

The biodegradation behaviour in soil presented compelling evidence for accelerated material breakdown. Whilst neat PLA exhibited no mass loss after 90 days of soil burial, PLA/PCP compounds demonstrated progressive degradation ranging from 5% to 64% depending on composition. Formulations containing 70% PCP achieved mass losses of 53–64%, substantially higher than the 5–9% observed for 30% PCP compounds (Possari et al., 2025). Molecular weight analysis revealed that specific formulations – PLA_30PCP60Gly and PLA_70PCP40Gly – exhibited accelerated PLA chain scission, with weight-average molecular weight reductions of 21% and 29% respectively, compared to 14% for neat PLA. This enhanced degradation is attributed to increased hydrophilicity, greater surface accessibility to microorganisms, and the presence of readily biodegradable CP components (Duarte et al., 2024; Lucas et al., 2008).

Conclusions and applications

This research demonstrates a viable pathway for circular economy implementation in the polymer industry by directly converting orange processing waste into functional bioplastic materials. The optimal formulation identified – containing 30% PCP with 60% glycerol – achieved doubled elongation compared to neat PLA while maintaining relatively modest reductions in stiffness and strength, alongside accelerated biodegradation kinetics (Possari et al., 2025). However, the study also highlighted trade-offs between biomass valorisation extent and mechanical performance, with the maximum citrus pulp incorporation (42% in the PLA_70PCP40Gly formulation) yielding materials with significantly reduced mechanical properties but excellent degradation characteristics.

The developed PLA/PCP compounds present promising candidates for semi-rigid packaging, disposable utensils, and short-life products where biodegradability is prioritised. Future research directions include exploring bio-based plasticiser alternatives to glycerol, investigating pre-treatment protocols to enhance CP integration, and evaluating barrier properties and long-term stability (Possari et al., 2025). This work contributes to the broader effort of developing sustainable materials that simultaneously address plastic pollution and agricultural waste management, demonstrating how food industry side streams can be transformed into value-added products rather than environmental liabilities (Otoni et al., 2021).

#Wasteless

Dario Dongo

Cover image: Possari et al. (2025). Graphical abstract

References

- Duarte, A. V., Possari, L. T., Gonçalves, L. M. G., Bonse, B. C., Rigolin, T. R., & Bettini, S. H. P. (2024). Accelerating degradable composite breakdown using citrus processing side streams. ACS Sustainable Resource Management, 1, 344–354. https://doi.org/10.1021/acssusresmgt.3c00108

- Lucas, N., Bienaime, C., Belloy, C., Queneudec, M., Silvestre, F., & Nava-Saucedo, J. E. (2008). Polymer biodegradation: Mechanisms and estimation techniques – A review. Chemosphere, 73(3), 429–442. https://doi.org/10.1016/j.chemosphere.2008.06.064

- Otoni, C. G., Azeredo, H. M. C., Mattos, B. D., Beaumont, M., Correa, D. S., & Rojas, O. J. (2021). The food–materials nexus: Next generation bioplastics and advanced materials from agri-food residues. Advanced Materials, 33(28), 2102520. https://doi.org/10.1002/adma.202102520

- Panwar, D., Saini, A., Panesar, P. S., & Chopra, H. K. (2021). Unraveling the scientific perspectives of citrus by-products utilisation: Progress towards circular economy. Trends in Food Science & Technology, 111, 549–562. https://doi.org/10.1016/j.tifs.2021.03.018

- Possari, L. T., de Paula, M. S., Nunes, G. F., Reis, I. A., Basaglia, M. V., Otoni, C. G., & Bettini, S. H. P. (2025). Bioplastics from orange processing waste and poly(lactic acid). Future Foods, 11, 100670. https://doi.org/10.1016/j.fufo.2025.100670

- Song, P., Chen, G., Wei, Z., Zhang, W., & Liang, J. (2013). Calorimetric analysis of the multiple melting behavior of melt-crystallized poly(L-lactic acid) with a low optical purity. Journal of Thermal Analysis and Calorimetry, 111(2), 1507–1514. https://doi.org/10.1007/s10973-012-2502-4

Dario Dongo, lawyer and journalist, PhD in international food law, founder of WIISE (FARE - GIFT - Food Times) and Égalité.