The conversion of industrial CO₂ into single-cell proteins (SCP) offers a promising route for sustainable animal feed production in China. Recent developments – including groundbreaking regulatory approvals, expanded pilot projects, advanced biotechnology innovations, and strengthened national climate commitments – underscore this innovation’s growing industrial momentum and policy support.

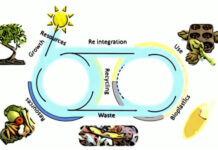

This article analyses the technological pathways, environmental and economic impacts, current challenges, and strategic approaches that can drive the transition towards food systems based on circular economy principles and low carbon emissions. It adopts a perspective of scientific diplomacy and international cooperation, both considered essential to achieving climate goals, food security, and the sustainable development of agri-food systems.

Introduction

China accounts for approximately 12% of global greenhouse gas emissions in agriculture, with livestock and aquaculture being major contributors. The country faces a critical protein shortage, consuming approximately 70 million tonnes of feed protein in 2024 with an import dependency ratio exceeding 80% (China Daily, 2025; Xinhua, 2025).

Under mounting pressure to meet its climate commitments – including carbon intensity reduction targets for 2025 and carbon neutrality by 2060 – China is combining carbon capture technology with biotechnology to address growing protein demand while transforming CO₂ from a liability into a valuable resource.

Technological pathways

Gas fermentation technology

The primary method for CO₂ upcycling involves gas fermentation using species such as Clostridium autoethanogenum to convert carbon monoxide (CO) and CO₂ into protein-rich biomass:

- Beijing Shougang LanzaTech achieved a world-first in 2021, establishing industrial-scale production with a capacity of 10,000 metric tons annually, reaching up to 85% protein conversion efficiency with a 22-second synthesis rate (China Daily, 2021; Feed Strategy, 2021);

- the technology utilizes industrial exhaust gas containing CO, CO₂, and ammonia as main raw materials, producing protein content twice that of soybean meal.

Recent Chinese research also demonstrated a parallel breakthrough in CO₂ upcycling by converting carbon dioxide and hydrogen into starch via an eleven-step hybrid chemoenzymatic process, offering further validation of CO₂ as a viable feedstock for essential macronutrients (Cai et al., 2021).

Dual-reactor systems

Chinese researchers have developed an innovative dual-reactor system integrating anaerobic and aerobic processes:

- in the first phase, microbial electrosynthesis (MES) converts CO₂ into acetate, which then feeds aerobic bacteria from the genus Alcaligenes to produce SCP;

- this system yields 17.4 g/L of dry cell weight with an impressive 74% protein concentration – significantly surpassing conventional protein sources like fishmeal and soybeans (Interesting Engineering, 2025; Yahoo News, 2025).

Yeast-based biotechnology

In a landmark development, China’s Ministry of Agriculture and Rural Affairs (MARA) approved Yarrowia lipolytica yeast protein as a new feed material in July 2025:

- developed by Beijing-based GTLB, this bio-fermentation technology captures CO₂ from coal chemistry, natural gas processing, and steelmaking industries, converting it into high-value yeast protein with production efficiency thousands of times greater than traditional agricultural methods;

- a 10-hectare facility can produce 100,000 tonnes annually—equivalent to soy protein from 40,000 hectares of farmland (China Daily, 2025; People’s Daily Online, 2025; TV BRICS, 2025).

Industrial-scale projects and commercialization

China’s CO₂-to-protein sector has entered commercial deployment:

- Shougang LanzaTech, now pursuing a Hong Kong Stock Exchange listing, has established four major production bases across China, including the world’s first industrial fermentation facilities for steel plant and ferroalloy industrial exhaust:

- the company plans to develop sustainable aviation fuel (SAF) production with construction beginning in northwest China in 2025, targeting 50,000 tons annual capacity by 2026 (Futu News, 2025);

- the production of 10 million tons of clostridium protein could replace 28 million tons of imported soybeans while reducing 250 million tons of CO₂ emissions – a significant contribution to both food security and climate goals (China Daily, 2021; ECNS, 2021).

Environmental & economic impacts

Climate mitigation benefits

Single-cell Protein (SCP) systems based on CO₂ upcycling demonstrate substantial climate benefits. China’s emissions fell by 1.6% year-on-year in the first quarter of 2025 and by 1% in the latest 12 months, with power-sector emissions falling 2% year-on-year in the 12 months to March 2025 (Carbon Brief, 2025a).

This historic shift – where clean energy growth drove emissions reduction despite rising power demand – creates favorable conditions for carbon-circular industries.

Carbon footprint of poultry farming

Research indicates that poultry (including duck) has relatively low carbon intensity among meat products, with duck meat showing approximately 2.07 kg CO₂eq/kg (Shrink That Footprint, 2023).

The integration of CO₂-derived proteins could further reduce these emissions, particularly as China’s livestock sector contributed to the country being responsible for 30% of global GHG emissions in 2023 (Sustainability Magazine, 2025).

Policy framework and strategic alignment

Carbon footprint management system

On 2 January 2025, the Ministry of Ecology and Environment of the People’s Republic of China (MEE), together with other relevant ministries, issued the Guidelines for the Preparation of Product Carbon Footprint Accounting Standards, establishing a unified framework for carbon accounting (Sino-German Cooperation on Climate Change, 2025a).

In January 2025, MEE released the national electricity carbon footprint for 2023, reflecting an average carbon intensity of 0.6205 kg CO₂e/kWh, providing essential baseline data for calculating product carbon footprints (Sino-German Cooperation on Climate Change, 2025b).

National climate commitments

In April 2025, President Xi Jinping announced that China would set new goals to cut emissions by 2035 ’covering the entire economy, including all greenhouse gases’ ahead of the COP30 summit in November (Climate Change News, 2025).

This comprehensive approach represents China’s first all-sector, all-gas climate plan, signaling unprecedented political commitment to carbon reduction.

Challenges and future directions

Technical and economic barriers

The economic viability of CO₂-derived SCP remains constrained by high renewable hydrogen costs and capital-intensive fermentation infrastructure.

While production costs are declining, achieving price parity with conventional protein sources requires continued technological optimization and economies of scale.

Regulatory development

Feed safety standards for CO₂-derived proteins are still evolving. The recent approval of Yarrowia lipolytica yeast protein marks important progress, and it is reasonable to expect regulatory developments that also cover other types of SCP to ensure market confidence and food safety.

Scaling imperatives

China can produce at least 1.2 trillion cubic meters of CO-rich industrial exhaust gas annually. Full utilization through biological fermentation could yield 10 million tons of microbial protein yearly, fundamentally transforming the protein supply landscape (Carbon Monoxide Becoming New Source of Protein, 2021).

Interim conclusions

China’s CO₂-to-feed technologies have transitioned from experimental pilots to early industrial deployment, supported by breakthrough regulatory approvals, demonstrated environmental benefits, and strengthened policy frameworks. The July 2025 approval of yeast-based CO₂ protein and the development of high-efficiency dual-reactor systems mark pivotal advances.

Combined with President Xi’s comprehensive climate commitments and the establishment of national carbon footprint standards, these developments position CO₂-derived proteins as a cornerstone of China’s carbon neutrality strategy.

Success will depend on continued technological innovation, cost reduction through scale, and integration with carbon credit markets. As China approaches COP30 with new climate ambitions, CO₂-to-protein technologies offer a compelling model for transforming industrial emissions into sustainable food systems – a critical convergence of climate action and food security imperatives.

EU protein strategy and parallel CO₂ upcycling initiatives

The European Union’s commitment to CO₂-to-protein technologies in turn demonstrates the potential of a global convergence with China’s approach. In October 2023, the European Parliament adopted a comprehensive European Protein Strategy resolution, emphasizing the need to reduce the EU’s heavy reliance on imported proteins while promoting sustainable production of both plant- and animal-based proteins (European Parliament, 2023). The resolution specifically identifies fermentation products and alternative proteins as viable sources within a circular economy framework (FoodTimes, 2023).

This strategic alignment is reinforced by substantial EU-funded research initiatives: the Novo Nordisk Foundation and Bill & Melinda Gates Foundation consortium invested €27 million in a groundbreaking project with Novozymes, Topsoe, Washington University, and Aarhus University’s CORC to convert CO₂ into acetate for protein production, potentially feeding 1 billion people annually (Novo Nordisk Fonden, 2023; Europabio, 2024).

The EU’s Horizon Europe program allocated €25 million to cultivated and fermented protein research in 2022 (Good Food Institute Europe, 2022), while the European Innovation Council backed Solar Foods’ Hydrocow project to produce dairy proteins from CO₂ and electricity (Solar Foods, 2024). Deep Branch’s PROTON project, funded under Horizon 2020, demonstrates industrial-scale CO₂-to-protein conversion achieving 70% protein content (CORDIS, 2020; Horizon Magazine, 2022).

These parallel developments – alongside China’s regulatory breakthroughs and industrial deployments – signal a critical global shift where CO₂ upcycling transcends regional boundaries to become a cornerstone of planetary food security and climate mitigation strategies. The convergence of Eastern industrial momentum with Western research innovation creates unprecedented opportunities for technology transfer, joint ventures, and the acceleration of carbon-circular protein systems worldwide.

Postscriptum – CO₂ upcycling as a diplomatic imperative

CO₂ upcycling is no longer merely a technological frontier – it is a geopolitical necessity and a testbed for scientific diplomacy. As demonstrated by cross-border CCUS hubs (e.g., Northern Lights, Sinopec) and joint research initiatives, carbon conversion technologies can transcend competition to build shared climate resilience. For this potential to be realized, three pillars are critical:

- Academia-industry-policy nexus. Foster open-access IP frameworks and co-investment models (e.g., UNFCCC Climate Funds) to de-risk scale-up and democratize access;

- Diplomatic infrastructure. Leverage CO₂ projects as trust-building instruments -embedding them in bilateral/multilateral pacts (e.g., COP29 action tracks) to align climate justice with economic reciprocity;

- Planetary stewardship. Treat every ton of converted CO₂ not just as emissions avoided, but as a currency of cooperation – turning waste into bridges between nations.

The path forward demands we reframe carbon innovation: not as a race for dominance, but as a shared project of human ingenuity. Let CO₂ upcycling become the blueprint for a new era of science-led peace.

Dario Dongo

Cover art copyright © 2025 Dario Dongo (AI-assisted creation)

References

- 350.org. (2025, April 24). Global: 350.org reacts to Xi Jinping pledging China’s first all-gas, all sector climate plan before COP30. https://350.org/press-release/global-350-org-reacts-to-xi-jinping-pledging-chinas-first-all-gas-all-sector-climate-plan-before-cop30/

- Aquafeed.com. (2021, November 4). China to produce single-cell protein from carbon monoxide. https://www.aquafeed.com/products/suppliers-news/china-to-produce-single-cell-protein-from-carbon-monoxide/

- Cai et al. (2021). Cell-free chemoenzymatic starch synthesis from carbon dioxide. Science 373:1523-1527. https://doi.org/10.1126/science.abh4049

- Clark, A. (2025, April 24). Xi commits China to tougher emissions targets at climate talks without US. Bloomberg https://www.bloomberg.com/news/articles/2025-04-24/xi-commits-china-to-tougher-climate-targets-as-us-retreats

- Cai et al. (2021). Cell-free chemoenzymatic starch synthesis from carbon dioxide. Science 373:1523-1527, https://doi.org/10.1126/science.abh4049

- Carbon Brief. (2025a, June 12). Analysis: Clean energy just put China’s CO2 emissions into reverse for first time. https://www.carbonbrief.org/analysis-clean-energy-just-put-chinas-co2-emissions-into-reverse-for-first-time/

- Carbon Brief. (2025b, May 15). China first quarter emissions fell despite rising power demand. https://www.carbonbrief.org/daily-brief/china-first-quarter-emissions-fell-despite-rising-power-demand/

- Carbon Brief. (2025c, May 8). China briefing 1 May 2025: Xi steadfast on climate; Solar and wind surpassed thermal power; Controlling short-term GHGs. https://www.carbonbrief.org/china-briefing-1-may-2025-xi-steadfast-on-climate-solar-and-wind-surpassed-thermal-power-controlling-short-term-ghgs/

- Carbon Monoxide Becoming New Source of Protein. (2021, November 11). Sci-Tech News. China.org.cn. http://www.stdaily.com/English/ChinaNews/2021-11/11/content_1231169.shtml

- Centre for Research on Energy and Clean Air. (2025, May 7). Will China fulfil its key climate pledge? https://energyandcleanair.org/will-china-fulfil-its-key-climate-pledge/

- China Briefing. (2023, July 25). Carbon labeling on products: Global practice and implementation in China. https://www.china-briefing.com/news/carbon-labeling-on-products-global-practice-and-implementation-in-china/

- China Briefing. (2024, November 4). Decoding China’s carbon accounting plan: Compliance and opportunities. https://www.china-briefing.com/news/china-carbon-accounting-plan-green-compliance-opportunities/

- China Briefing. (2025, July 10). China’s carbon targets – How far has it come in 2025? https://www.china-briefing.com/news/tracking-chinas-carbon-targets-how-far-has-it-come-in-2025/

- China Daily. (2021, November 1). New protein can lessen reliance on imported soybean. http://www.chinadaily.com.cn/a/202110/31/WS617e8cd0a310cdd39bc72631.html

- China Daily. (2025, July 3). China approves CO2-turned protein as feed material. https://www.chinadaily.com.cn/a/202507/03/WS68663e01a31000e9a5739fb1.html

- Climate Change News. (2025, April 24). Xi commits China to full climate plan, but emissions-cutting ambition still unclear. https://www.climatechangenews.com/2025/04/24/xi-commits-china-to-full-climate-plan-but-emissions-cutting-ambition-still-unclear/

- CORDIS. (2020). Recycling industrial CO2 into cost-competitive protein for high-value, sustainable animal feed. European Commission https://cordis.europa.eu/project/id/101010113/reporting

- ECNS. (2021, November 1). New protein can lessen reliance on imported soybean. http://www.ecns.cn/news/sci-tech/2021-11-01/detail-ihasnqih0806206.shtml

- European Parliament. (2023). Resolution on European protein strategy (2023/2015(INI)). https://www.europarl.europa.eu/doceo/document/TA-9-2023-0375_EN.html

- Europabio. (2024). Transforming CO2 into proteins. https://www.europabio.org/transforming-co2-into-proteins/

- Feed Strategy. (2021). Chinese researchers create feed from carbon monoxide. https://www.feedstrategy.com/sustainability-in-feed-production/agriculture-technology/article/15442538/chinese-researchers-create-feed-from-carbon-monoxide

- Futu News. (2025, February 17). Shougang Longze is sprinting for a listing on the Hong Kong Stock Exchange. https://news.futunn.com/en/post/53247220/shougang-longze-is-sprinting-for-a-listing-on-the-hong

- Good Food Institute Europe. (2022). Horizon Europe announces €25 million for sustainable proteins. https://gfieurope.org/blog/horizon-europe-announces-e25-million-for-sustainable-proteins/

- Horizon Magazine. (2022). Making carbon dioxide into protein for innovative animal feed. European Commission. https://ec.europa.eu/research-and-innovation/en/horizon-magazine/making-carbon-dioxide-protein-innovative-animal-feed

- Interesting Engineering. (2025, January 16). CO2 into nutritious food: Chinese scientists achieve 74% protein yield. https://interestingengineering.com/science/scientists-transform-co2-to-high-protein-food

- Novo Nordisk Fonden. (2023). CO2 as a sustainable raw material in our future food production. https://novonordiskfonden.dk/en/news/co2-as-a-sustainable-raw-material-in-our-future-food-production/

- People’s Daily Online. (2025, July 3). China approves CO2-turned protein as feed material. https://en.people.cn/n3/2025/0703/c90000-20335655.html

- S&P Global. (2025, April 24). China can meet most 2025 climate targets, except carbon intensity goal: Report. https://www.spglobal.com/commodity-insights/en/news-research/latest-news/energy-transition/042425-china-can-meet-most-2025-climate-targets-except-carbon-intensity-goal-report

- Shrink That Footprint. (2023, November 22). The most environmentally friendly meat – Carbon footprint of meats. https://shrinkthatfootprint.com/the-most-environmentally-friendly-meat-choosing-your-options/

- Sino-German Cooperation on Climate Change. (2025a, May 19). China strengthened its carbon footprint management system. https://climatecooperation.cn/climate/china-strengthened-its-carbon-footprint-management-system/

- Sino-German Cooperation on Climate Change. (2025b, July 8). China releases 2025 report on product carbon footprint management. https://climatecooperation.cn/climate/china-releases-2025-report-on-product-carbon-footprint-management/

- Solar Foods. (2024). Milk from carbon dioxide and electricity. Retrieved from https://solarfoods.com/milk-from-carbon-dioxide-and-electricity/

- Sustainability Magazine. (2025, April 24). Energy & EVs: How will China hit its 2035 carbon targets? https://sustainabilitymag.com/articles/energy-evs-how-will-china-hit-its-2035-carbon-targets

- The Western Producer. (2021, November 1). China to make protein for livestock from carbon monoxide. https://www.producer.com/news/china-to-make-protein-for-livestock-from-carbon-monoxide/

- TV BRICS. (2025, July 3). China approves CO2-turned protein as new sustainable animal feed material. https://tvbrics.com/en/news/china-approves-co2-turned-protein-as-new-sustainable-animal-feed-material/

- World Resources Institute. (2025, April 17). A look at China’s corporate carbon accounting platform. https://www.wri.org/technical-perspectives/china-corporate-carbon-accounting-rating-platform-explained

- Xinhua. (2025, July 3). China approves CO2-turned protein as feed material. https://english.news.cn/20250703/db22039bfc32436dae0838f3aa618c1e/c.html

- Yahoo News. (2025, January 16). Chinese scientists convert CO2 into nutritious food with 74% protein yield. https://www.yahoo.com/news/chinese-scientists-convert-co2-nutritious-160027502.html

Dario Dongo, lawyer and journalist, PhD in international food law, founder of WIISE (FARE - GIFT - Food Times) and Égalité.